SKD61 Hot Work Die Steel is a medium alloy hot work die steel containing silicon, chromium, molybdenum and vanadium. After quenching and tempering treatment, it obtains a martensitic structure with fine structure and moderate grains. It is basically distributed with fine carbides and has good properties. It has comprehensive mechanical properties and good hardenability, which is more suitable for manufacturing molds with large sizes and complex shapes.

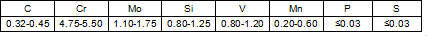

Chemiscal composition

Heat treatment process:

(1) Preheating: The temperature is 600-630 ℃, holding time is 1.5-2.0 hours (It depends on the mold size). Then heat it to 830-850℃,and the heat preservation time is 1.5-2.0 hours. The process is called pretreatment before quenching, which can reasonably adjust the internal microscopic defects of workpiece that is necessary for quenching.

(2) Quenching: On the basis of pretreatment, heat it to 1040-1080℃, keep the temperature for 2.0-2.5 hours, and then have oil quenching out of the furnace.

(3) Tempering: After quenching, the mould has a larger internal stress inside. It must be tempered to the workpiece in 1~2h in order to eliminate the stress caused by quenching. What’s more, it should also be uniform heating before tempering workpiece to avoid cracking. The specific method is: heating the workpiece to 380-400℃ for 1 hours’ heat preservation and then slowly heat it to 580-600℃. After a tempering and 2h’s heat preservation time, the natural air cooling to room temperature after two times tempering with the temperature 560-580℃ and the preservation time is 2h. Then air cooling is outside the furnace.

According to the heat treatment process, it is necessary to add that: Because H13 (4Cr5MoSiV1) steel is very sensitive to the quenching temperature, and it has excellent quenching performance at high temperature, so quenching in high temperature is needed.

(4) Nitridation: The surface hardness can reach 1000 - 1250HV after soft nitriding treatment at 525 ℃. Nitriding time for 20 hours, 30 hours and 60 hours, the depth of the hardened layer were 0.20mm, 0.25 mm, 0.30 mm. Soft nitriding treatments at 575 ℃, working surface hardness of about 950HV. Usually soft nitriding for 2 hours, the depth of the hardened layer is 10 - 20um.

The specialty of the steel:

SKD61 Hot Work Die Steel is a medium alloy hot work die steel containing silicon, chromium, molybdenum and vanadium. After quenching and tempering treatment, it obtains a martensitic structure with fine structure and moderate grains. It is basically distributed with fine carbides and has good properties. It has comprehensive mechanical properties and good hardenability, which is more suitable for manufacturing molds with large sizes and complex shapes.The corresponding foreign brand of SKD61 steel is 4Cr5MoSiV1 steel、DIN 1.2344、ASTM H13.

Main uses:

It is suitable for making aluminum, zinc, copper alloy extrusion die, die casting, hot forged die, and hot shear blades. What’s more, it’s the ideal material for making top rod and sleeve, as well as producing high yield of plastic mold.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat