1.2379 steel is Ledeburitic 12% chrome steel, very high resistanceagainst abrasive and adhesive wear due to a highvolume of hard carbides in the steel matrix, goodtoughness,very gooddimensional stability, highcompressive strength, very good base material forPVD/CVD coating as well as nitriding due to itssecondary hardening properties.

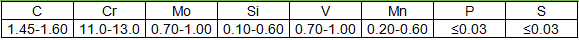

Chemiscal composition:

Heat Treatment:

Forge: at 900℃-1100℃ Cool slowly and anneal immediately

Annealing: at 830℃-860℃ Cool slowly in furnace

Stress Relieving: at to 650℃-700℃ Cool in furnace or still air

Hardening: Preheat at 650℃-850℃ raise to 1000℃-1050℃ Cool in air, oil or into hot bath held at 500℃-550℃ and then air cool

AISI d2 tool steel hardness Annealed 255.

The specialty of the steel:

DIN 1.2379 steel is versatile high-carbon, high-chromium, air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous, large, chromium-rich alloy carbides in the microstructure.

Main uses:

Cutting, punching, stamping tools, shear blades, thread rolling dies, cold extrusion dies, drawing and bending tools, flanging and straightening rolls, fine cutting tools deep drawing tools, plastic moulds for abrasive polymers

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat