Cr12MoV steel has good wear resistance, hardenability, toughness, thermal stability, compressive strength, micro-deformation, excellent overall performance and wide adaptability.

Cr12MoV is used to manufacture various cold stamping molds and tools with large cross-sections, complex shapes, and heavy working conditions, such as punching dies, trimming dies, rolling dies, steel plate Cr12Mov thick plate deep drawing dies, round Saws, standard tools and gauges, thread rolling dies, etc.

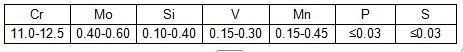

Chemiscal composition:

Heat Treatment:

Forge: At 1065℃ and then down to 950℃

Annealing: At 886℃ Cool slowly in furnace

Stress Relieving: Heat to1050-850℃

Tempering: Be tempered at 204°C for achieving Rockwell C hardness of 61 and at 537°C for a Rockwell C hardness of 54.

The specialty of the steel:

Cr12MoV Cold Work Tool Steel has high hardenability,, toughness, thermal stability, compressive strength, micro-deformation, and excellent comprehensive performance, with wide adaptability characteristics. And it has good machinability and thermal oxidation resistance. The softening temperature under heat is 520℃. It has high wear resistance (3-4 times higher than ordinary low alloy tool steel) and small quenching volume deformation.

Main uses:

Cr12MoV tool steel is widely used to make cold working dies with large section, complex shape, large impact force and high wear resistance, such as silicon steel sheet die, wire drawing die, cold cutting scissors, edge cutting die, edge rolling die, wire rubbing plate, punching die, steel plate deep drawing die, punch, etc.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat