1.2083/S136/4Cr13

DIN 1.2083 steel mainly applies to production of PVC mold, wear resistance and fillers, including hot hard plastic molds, long life molds, production of optical product components, such as cameras and solar lenses, medical containers, laser CDs, etc.

Sample testing of 1.2083 steel will be done on each batch as per the standard,1.2083 steel will be not only done by mill itself, also will be done by third party. In this way, the quality can get double assurance.

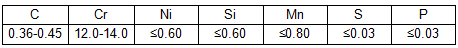

Chemiscal composition:

Heat Treatment:

Forge: at 900℃-1100℃ Cool slowly and anneal immediatedly

Anneal: at 880℃ Cool slowly in furnace

Stress Relieve: at to 600℃-650℃ Cool in still air

Harden: Preheat at 600℃-850℃ raise to 1020℃-1100℃ Cool in air, iol or into salt bath held at 200℃-300℃ and then air cool

The specialty of the steel:

DIN 1.2083 steel Corrosive Resistance And Super Mirror-like. Stainless martensitic with a high hardenability, good polishing properties, excellent resistance to corrosion and hot oxidation. Annealing hardness HB 235max. Prehardened to HRC 30-36 mirror-like to easy machining, deformation effected by hardened could off.

Main uses:

Its applications are plastic mould, particularly for acid aggressive plastics (e. g acetate and PVC), or plastic containing abrasive fillers. Suited for the manufacture of glass, such as moulds of optical products.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat