P20+Ni

Similar as 1.2738.

The corresponding foreign brand of 1.2738 is P20+Ni 、718HH、3Cr2NiMo

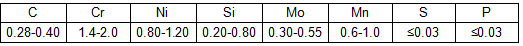

Chemiscal composition:

Heat Treatment:

Step 1: Annealing

Heat to 720-740°C, hold for 2-4 hours, with the furnace cooling to 500°C after air cooling.

Hardness: The hardness after annealing is about 180-220 HB.

Step 2: Quench

Heat to 840-880°C, keep warm and cool in oil or air.

- Note: P20+Ni die steel has good hardenability, and the hardness after quenching can reach 50-55 HRC.

Step 3. Temper

- Low temperature tempering (150-250°C) : high hardness, suitable for high wear resistance requirements of the mold.

- Medium temperature tempering (400-500°C) : balance of hardness and toughness, suitable for general molds.

- High temperature tempering (500-600°C) : low hardness, good toughness, suitable for high toughness requirements of the mold.

Hardness: The hardness after tempering is usually 30-40 HRC.

The specialty of the steel:

1. Good processing performance: pre-hard state can be directly processed to reduce heat treatment processes.

2. Excellent polishing performance: Suitable for molds with high finish requirements.

3. Wear resistance and toughness balance: suitable for complex mold manufacturing.

Main uses:

1. Suitable for manufacturing large, complex plastic mold, such as auto parts, home appliance shell, etc.

2. High finish mold : Suitable for manufacturing molds with high finish requirements, such as transparent plastic products.

3. Pre-hard state use : Usually used in the pre-hard state, the hardness is about 30-36 HRC, can be directly processed without heat treatment.

4. Long life mold: Suitable for molds requiring long life and high wear resistance.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat