1.7225/SCM440/42CrMo4

Medium carbon chromium-molybdenum alloy steel SCM440, an alloy steel containing chromium and molybdenum. It has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer, and few surface defects. Easy to spheroidize and has low cold cracking rate. Alloy steel SCM440 is usually hardened and tempered. The ultimate tensile strength is 850-1000Mpa. This material strikes a very good balance between strength, toughness and wear resistance. The alloy's chromium content provides good hardness penetration, while the molybdenum element imparts average hardness and high strength.

Alloy steel SCM440 responds well to heat treatment and is easy to process under heat treatment conditions. This material offers many desirable properties such as good strength and wear resistance, excellent toughness, good ductility and resistance to high temperature stress.Our company can provide SCM440 hot-rolled or forged materials, etc.

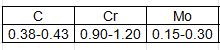

Chemiscal composition:

Heat Treatment:

1. anneal

- Objective: To reduce hardness and improve machinability.

- Process: heating to 800-850°C, slowly cooling after holding.

2. normalizing

- Objective: refine grain and uniform structure.

- Process: heating to 850-900°C, cooling in the air after holding.

3. quench

- Purpose: To improve hardness and strength.

- Process: heating to 830-880°C, rapid cooling after holding (oil or water quenching).

4. temper

- Objective: To eliminate quenching stress and improve toughness.

- Process: Heating to 150-200°C (low temperature tempering) or 400-600°C (high temperature tempering) after quenching, cooling after holding.

5. carburizing

- Objective: To improve surface hardness and wear resistance.

- Process: Carburizing at 900-950°C, followed by quenching and low temperature tempering.

The specialty of the steel:

SCM440 is a medium carbon chromium molybdenum steel with the following characteristics:

- High strength: After proper heat treatment, with high strength and hardness.

- Good toughness: While maintaining strength, it has good toughness.

- Wear resistance: suitable for wear conditions.

- Hardenability: Chromium and molybdenum elements improve its hardenability, suitable for heat treatment of large section parts.

- Fatigue strength: suitable for parts subjected to alternating loads.

Main uses:

The SCM440 is widely used to manufacture parts that require high strength, wear resistance and toughness. Typical applications include:

- Gears: Gears in automobiles and construction machinery.

- Shaft parts: drive shaft, crankshaft, etc.

- Bolts and nuts: high strength bolts and nuts.

- Tools and molds: such as stamping molds, plastic molds, etc.

- Other mechanical parts: such as connecting rods, pins, etc.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat