SCM415 is a low alloy chromium molybdenum steel with the following characteristics:

High strength: After proper heat treatment, with high strength and hardness.

Good toughness: While maintaining strength, it has good toughness.

Wear resistance: suitable for wear conditions.

Hardenability: Chromium and molybdenum elements improve its hardenability, suitable for heat treatment of large section parts.

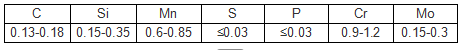

Chemiscal composition:

Heat Treatment:

1. anneal

-Objective: To reduce hardness and improve machinability.

-Process: heating to 800-850°C, slowly cooling after holding.

2. normalize

- Objective: refine grain and uniform structure.

- Process: heating to 850-900°C, cooling in the air after holding.

3. quench

- Purpose: To improve hardness and strength.

- Process: heating to 830-880°C, rapid cooling after holding (oil or water quenching).

4.temper

- Objective: To eliminate quenching stress and improve toughness.

- Process: Heating to 150-200°C (low temperature tempering) or 400-600°C (high temperature tempering) after quenching, cooling after holding.

5.carburizing

- Objective: To improve surface hardness and wear resistance.

- Process: Carburizing at 900-950°C, followed by quenching and low temperature tempering.

The specialty of the steel:

SCM415 is a low alloy chromium molybdenum steel with the following characteristics:

- High strength: After proper heat treatment, with high strength and hardness.

- Good toughness: While maintaining strength, it has good toughness.

- Wear resistance: suitable for wear conditions.

- Hardenability: Chromium and molybdenum elements improve its hardenability, suitable for heat treatment of large section parts.

Main uses:

The SCM415 is widely used to manufacture parts that require high strength, wear resistance and toughness. Typical applications include:

- Gears: Gears in automobiles and construction machinery.

- Shaft parts: drive shaft, crankshaft, etc.

- Bolts and nuts: high strength bolts and nuts.

- Other mechanical parts: such as connecting rods, pins, etc.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province