A8 cold work steel is similar to A2,S7.

The toughness is twice as high as SKD11 cold working steel, making complex dies, and the tensile die has large anti-cracking and collapsing properties. The mold is tempered at 520-530℃, and the hardness is still 61-63HRC, which reduces the cracking accident caused by residual stress of the wire-cutting mold.

3. Suitable for surface hardening treatment, so that the mold life is longer.

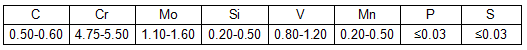

Chemiscal composition:

Heat Treatment:

830℃~880℃ slow cooling

The specialty of the steel:

1. The toughness is twice as high as SKD11 cold working steel, making complex dies, and the tensile die has large anti-cracking and collapsing properties

2. The mold is tempered at 520-530℃, and the hardness is still 61-63HRC, which reduces the cracking accident caused by residual stress of the wire-cutting mold.

3. Suitable for surface hardening treatment, so that the mold life is longer.

Main uses:

1. Suitable for making complex shape or stamping die, drawing die

2. Suitable for making cold working molds for wire cutting processing

3. Screw hobbing die, deep drawing forming die, stainless steel plate stamping die

4. High speed forging punch, cold forging die

5. Suitable for long life carpentry

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat