DC53/Cr8Mo2SiV Steel is a new type of cold-working die steel that improves SKD11, and its technical specification is set out in Japanese Industrial Standard (JIS)G4404. It overcomes the weakness of high temperature tempering hardness and toughness of SKD11, and will completely replace SKD11 in the field of general and precision molds.Our company provides DC53 steel round bar and DC53 steel plates

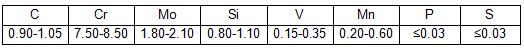

Chemiscal composition:

Heat Treatment:

Dense hardened layer structure was obtained on the surface of DC3 workpiece after nitriding treatment, which significantly improved the wear resistance and corrosion resistance of the workpiece. The hardness of the surface layer after gas nitriding at 525℃ is about 1250HV, and that after soft nitriding at 570℃ is about 950HV.

The specialty of the steel:

DC53 Steel is a new type of cold-working die steel that improves SKD11, and its technical specification is set out in Japanese Industrial Standard (JIS)G4404. It overcomes the weakness of high temperature tempering hardness and toughness of SKD11, and will completely replace SKD11 in the field of general and precision molds.

Main uses:

Precision blanking dies used for wire cutting of precision stamping dies, stamping dies for various purposes, tools for plastic deformation of difficult-to-machine materials, dies for cold forging, deep drawing and thread rolling, or other high-return blanking punches, stainless steel plate punches, etc.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat