H11/4Cr5MoSiV is one of the hot work chromium type tool steels belong to ASTM A681 standard. It has good strength in high temperature, excellent toughness and ductility in all z directions, excellent hardenability, and a high level of thermal shock and thermal fatigue resistance. AISI H11 steel can be deeply hardened by heat treatment and air quenching.

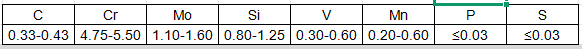

Chemiscal composition:

Heat Treatment:

Forge: at 1050℃-1095℃ Cool slowly and anneal then.

Annealing: at 843℃-898℃ Cool slowly in furnace

Stress Relieving: heat slowly to 566-676℃, and then cool in still air.

Hardening: Preheat to 815 ℃ and then heat to 1010℃ and hold for 15 to 40 minutes. Air cool (air quench)

The specialty of the steel:

AISI H11 Hot work tool steel is a 5% chromium hot work steel that is characterized by excellent impact toughness. It contains less vanadium than the widely-used H13 hot work tool steel. H11 is a deep-hardening, air-hardening steel that exhibits minimal size change during heat treatment. It has good resistance to thermal fatigue cracking (heat checking) and excellent resistance to gross cracking and thermal shock when water cooled in service. H11 is recommended for hot tooling applications where maximum resistance to cracking is required.

Main uses:

Hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies and extrusion tooling.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat