1.2601/D5/SKD10 steel is high carbon, high chromium type ledeburite cold work die steel, cobalt is not a required component unless there are special requirements. SKD10 mold steel has good hardenability, small heat treatment deformation, wear resistance and impact resistance

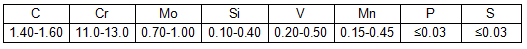

Chemiscal composition:

Heat Treatment:

Starting temperature 1000°C. Final flame temperature 800°C;Quenching temperature 950~1000°C, oil cooling or air cooling.

The specialty of the steel:

DIN1.2601 has high hardenability, hardenability, toughness, thermal stability, compressive strength, micro deformation and excellent overall performance. 1.2601 round steel has wide adaptability and other characteristics, and has good machining and Thermal oxidation resistance.

Main uses:

1.2601 German standard cold work die steel is widely used in aluminum and zinc die-casting mold materials. This steel contains tungsten components and is a high-temperature resistant high-grade alloy steel. It is suitable for hot work, aluminum, magnesium, zinc, and copper alloy die-casting molds, grooving knives, and scissors. And hot forging actions, plastic molds, hot work reamers, rolling knives, general hot work forging dies, hot bolt dies, various hot room tools, etc.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat