6CrW2Si alloy steel has excellent wear resistance, toughness and hardness. Its high hardness and high toughness enable it to maintain the cutting performance of the tool during high-speed cutting, while also resisting the risk of wear and fracture. In addition, 6CrW2Si also has good thermal properties Stability and corrosion resistance, able to work stably in high temperature, high pressure and corrosive environmentsl.

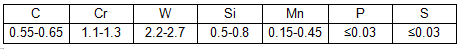

Chemiscal composition:

Heat Treatment:

Samples are quenched at 860~900℃ and oil cooled

The specialty of the steel:

6CrW2Si alloy steel has excellent wear resistance, toughness and hardness. Its high hardness and high toughness enable it to maintain the cutting performance of the tool during high-speed cutting, while also resisting the risk of wear and fracture. In addition, 6CrW2Si also has good thermal properties Stability and corrosion resistance, able to work stably in high temperature, high pressure and corrosive environmentsl.

Main uses:

Special steel 6CrW2Si has higher quenching hardness and certain high-temperature strength than 4CrW2Si steel and 5CrW2Si steel. Usually used to manufacture tools that withstand impact loads and require high wear resistance, such as pneumatic tools, chisels and stamping dies, cold shear blades, punching dies, air hammer tools, etc.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat