1.2360 ALLOY TOOL STEEL

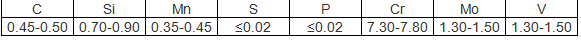

Chemiscal composition:

Heat Treatment:

- Annealing: Slow cooling after 860-900°C, annealing hardness ≤229 HBW.

- Quenching: 1020-1100°C oil or air cooling to obtain a uniform structure.

- Tempering: 500-650°C tempering, adjusting hardness and toughness, hardness after tempering 40-55 HRC.

The specialty of the steel:

1. High hardness and wear resistance:

After quenching and tempering, the hardness can reach 40-55 HRC (hot work) or 58-64 HRC (cold work), suitable for high load and high wear environment.

2. High temperature performance:

It maintains high strength and thermal stability at high temperature (400-600°C), thermal conductivity 33 W/(m·K), coefficient of thermal expansion 12.6-13.0×10⁻⁶/K.

3. Toughness and fatigue resistance:

Impact toughness ≥38 J/cm², tensile strength ≥980 MPa, can withstand cyclic load and thermal shock.

4. Processing performance:

Easy to form by milling, grinding, electric discharge machining (EDM) and other processes, suitable for complex mold manufacturing.

Main uses:

1. Hot working mold:

Die casting mold (aluminum alloy/magnesium alloy), forging mold (auto parts), extrusion mold (copper alloy).

2. Cold mold:

Cold stamping die, shear die, high precision cold extrusion die, suitable for electronic and medical device manufacturing.

3. Cutting tools:

High speed cutting tools, punching and shearing tools, excellent wear resistance and red hardness.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat