T10 steel is a high carbon tool steel with good hardness and wear resistance. It is suitable for making cutting tools and stamping dies. Its advantages include moderate hardness, strong toughness, low production cost, after heat treatment hardness can reach more than 60HRC. However, the hardenability of T10 Steel is low, heat resistance is poor, in the quenching heating is not easy to overheat, still maintain fine grain. In addition, toughness, strength and wear resistance are higher than T7-T9, but the thermal hardness is low, hardenability is still not high, quenching deformation

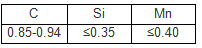

Chemiscal composition:

Heat Treatment:

Quench: 760~780℃ water cooling.

The specialty of the steel:

T10 steel is a high carbon tool steel with good hardness and wear resistance. It is suitable for making cutting tools and stamping dies. Its advantages include moderate hardness, strong toughness, low production cost, after heat treatment hardness can reach more than 60HRC. However, the hardenability of T10 Steel is low, heat resistance is poor, in the quenching heating is not easy to overheat, still maintain fine grain. In addition, toughness, strength and wear resistance are higher than T7-T9, but the thermal hardness is low, hardenability is still not high, quenching deformation.

Main uses:

It is commonly used for making long-cut blades and light-duty and small cold punching (punch) . Hardened plastic die steels are suitable for smaller plastic dies with low stress, simple shape and low deformation requirements. Used for core, punch, cavity plate, inlay, quench hardness 4652hrc, can also be used for small core and thermal plastic mold parts.

Contact: Amy Ruan

Phone: 0086-15897795404

E-mail: manager@risinmouldsteel.com

Whatsapp:0086-15897795404

Add: Sanyuan Road, Xisai Mountain Industrial Park, Huangshi City, Hubei Province

We chat